Honda Civic EK9 Type-R B16B – The Art of Automotive Engineering

Yes, I know…this is old topic, but, as engineering student, Honda Civic Type-R production is always give me a great inspiration “The quality never know the bound”! so, you can say, this is my tribute entry. I collected the fact and data from the internet. I recommend you to read this article if you are newbie about Honda VTEC before you scroll down.

This topic I would like to dedicate to the first model of Honda Civic Type-R , EK-9, the legendary, the legacy, the power of dream!

Introduction

The Honda Civic Type R is the highest performance version of the Honda Civic made by Honda Motor Company of Japan. It features a lightened and stiffened body, specially tuned engine and upgraded brakes and chassis. Red is also used in the interior to give it a special sporting distinction and to separate it from other Honda models. In Japan, a one-make series of Honda Type R cars where privateers can purchase an off-road Type R and compete in a series championship is a stepping stone for many aspiring racing drivers. Source :http://en.wikipedia.org/wiki/Honda_Civic_Type_R#Premier_Special_Edition

1st generation (EK9 chassis)

The first Civic to receive the ‘Type R’ name was based on the 6th-generation ‘EK’ Civic. The contributing base model was the JDM Civic 3-door hatchback called SiR, code named EK4. Like its big brother the Integra Type R DC2/JDM DB8, the Civic SiR’s transformation into a Type R was achieved by working on the base model and improving it to Honda’s idea of a car capable of high performance on the circuit.

The first Civic to receive the Type R badge was introduced in 1998 as the EK9. The EK9 shared many characteristics with the Integra Type R DC2/ JDM DB8 such as omission of sound deadening and other weight-reduction measures, a hand-ported B16B engine, front helical limited-slip differential and close ratio gearbox etc.. The B16B engine boasted one of the highest power output per litre of all time for an NA engine with 185 PS (136 kW; 182 hp) from a 1.6L. For the first time, a strategically seam weldedmonocoque chassis was used to improve chassis rigidity. The interior featured red Recaro seats,red Recaro door cards and red Recaro floor mat, a titanium shift knob and a Momo steering wheel. In 1999 the Type Rx was introduced featuring a CD player, body colored retractable electric door mirrors, power windows, auto air conditioning, key-less entry unlock system, aluminum sports pedals, and a carbon type center panel. The SiR badge from the previous 2 generations was ceded to the EK4 Civic as a mainstream sedan and hatchback which was sold in huge numbers across the globe due to its relatively low cost, practicality and everyday usable street performance/drivability.

- End of Introduction -

To make you clear, I’ll put the data that I collected from WWW, this the comparison between base model (EK-4) was also the great car and Type-R model (EK-9) improve from the great car and engine!

Body | ||

| Model Variant | VTi-R | TYPE R |

| Car Series | EK4 | EK9 |

| Year | 1995-1998 | 1997 – 2001 |

| Doors and Body Style | 3DR Hatch | 3DR Hatch |

| Engine Size | 1595cc B16A2 | 1595cc B16B Spec R |

| Fuel System | MULTI POINT F/INJ | MULTI POINT F/INJ |

| Cylinders | 4 | 4 |

| Transmission | 5M | 5M with LSD |

| Standard Features | 15″ Alloy Wheels, 4 Speaker Stereo, ABS (Antilock Brakes), Adjustable Steering Col. – Tilt & Reach, Air Conditioning, Airbags – Driver & Passenger (Dual), Central Locking, Engine Immobiliser, Paint – Metallic, Power Door Mirrors, Power Steering, Power Windows, Radio Cassette, Sunroof – Electric and Tilt, Suspension – Sports, Seats – Sport bucket, Centre Console with dual cup holder, Rear seat head restraints, Digital Clock | 15″ Alloy Wheels, Rear Spoiler, Momo Steering Wheel, Recaros |

| Optional Features | Central Locking, Power Windows, Power Mirrors, Power Steering, Radio Cassette with 4 Speakers, Dual Airbag Package, ABS | |

| Cosmetics | Leather wrapped MOMO Steering wheel with SRS airbag, Red Carpet, Red Arm rests, Red Floormats with Type R badging, Titanium gear shifter, Red stiched boot, Carbon centre dash console with Type R badge, Type R Instument cluster, Carbon dash bezel, Emergency Flare, No Coin holder, Red Recaro seats, Bodykit, Red exterior badging, Colour coded exterior panels, UV cut glass, Privacy glass, Red engine head cover, Aluminum radiator, Helical LSD | |

| Front Brakes | Vented Discs, ABS | Larger Vented Disc , ABS (optional) |

| Rear Brakes | Disc | Disc |

| Wheel Dimension | 195-55-15 | 195-55-15 Enkei 5 stud PCD |

| Turning Circle | 9.8m | 9.8m |

| Tank Capacity | 45 litres | 50litres |

| Exterior Length | 4180mm | 4185mm |

| Exterior Width | 1695mm | 1695mm |

| Exterior Height | 1375mm | 1360mm |

| Front Track | 1475mm | 1480mm |

| Rear Track | 1475mm | 1480mm |

| Wheel Base | 2620mm | 2620mm |

| Front Suspension | Ind; double wishbones with coil springs gas damper and stabiliser bars | Ind; double wishbones with coil springs gas damper |

| Rear Suspension | Ind; double wishbones with coil springs gas damper and stabiliser bars | Ind; double wishbones with coil springs gas damper and trailing link |

| Kerb Weight | 1105kg | 1059kg (97 Spec) 1089kg (98 Spec) |

| Ground Clearance | 106mm | 105mm |

| 1/4 Mile time | 16.2 | 15.5 |

Power Section

Engine

| ||

| Engine Type | B16A (1992-1995)JDM | B16B Spec R |

| Bore and Stroke | 81×87.2mm | 81×87.2mm |

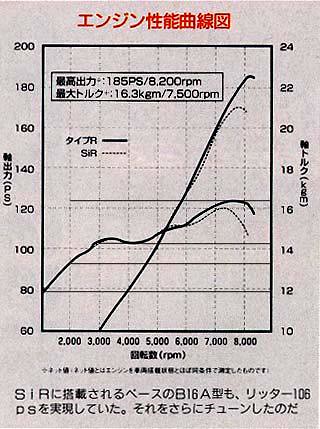

| Maximum Output | 170ps/7800rpm | 185ps/8200rpm |

| Maximum Torque | 16.0kg-m/7300rpm | 16.3kg-m/7500rpm |

| Bore x Stroke | 81.0×77.4mm | 81.0×77.4mm |

| Displacement | 1595cc | 1595cc |

| Compression | 10.4 | 10.8 |

| Maximum RPM | 8000rpm | 8400rpm |

| Valve Timing at 1mm liftIN Open/CloseEX Open/Close | BTDC15/ABDC45BBDC40/ATDC7 | BTDC18/ABDC45BBDC45/ATDC10 |

| Valve Lift | IN 10.7mm, EX 9.4mm | IN 11.5mm, EX 10.5mm |

| Inlet Valve Diamter | 33mm x 2mm | 33mm x 2mm |

| Spark Plug Type | Heat Rate #6 | Heat Rate #7 platinum |

| Throttle Bore Diameter | 60mm | 60mm |

| Intake Manifold | Single pipe sideflow | Single pipe sideflow |

| Air Intake Diameter | 65mm | 65mm |

| Exhaust Manifold | 4-to-2 | 4-to-2 |

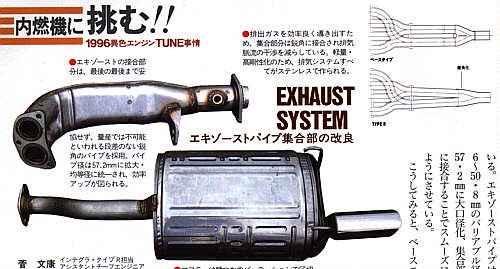

| Exhaust Pipe Diameter | 48.6-50.8mm | 57.2mm |

| Silencer Flow Capacity | 98liter/sec | 115liter/sec |

| Cam ProfileMax Lift (IN/EX)Open Timing (IN/EX)Close Timing (IN/EX) | 10.7/9.4BTDC15/BBDC40ABDC 45/ATDC 7 | 11.5/10.5BTDC 18/BBDC45BTDC 45/ATDC 10 |

| Connecting rod bearing width | 19.5 mm | Tetra-methyl lead coated crank 17.5 mm |

| Connecting rod | Chrome carbon steel | High chrome carbon steel |

| Piston | Molybdenum coated low friction | |

| Block Height | 263mm | 270mm |

Drivetrain

| ||

| LSD | Helical LSD | None |

| Code | S80 (S4C) | Y2 |

| Gear Ratio | ||

| 1st | 3.230 | 3.230 |

| 2nd | 2.105 | 2.105 |

| 3rd | 1.458 | 1.458 |

| 4th | 1.107 | 1.107 |

| 5th | 0.848 | 0.848 |

| Reverse | 3.000 | 3.000 |

| Final Gear Ratio | 4.400 | 4.400 |

The Masterpiece of Art!

So, what actually they (Honda’s Engineer) do? To create such a masterpiece, not an easy task, to create masterpiece (B16B) from already masterpiece (B16A) is very difficult task! And I’m here not only talked about power, because, with ‘aftermarket’ it’s very easy to archive as long as you have money, I’m more focus about balance, harmonic, durability, research and art!

On the below are the power curves for B16A 170ps versus B16B. Note the big gain in power after 6000rpm, the VTEC switch-over point between mild and wild cam profiles. The gain at extreme high rpms is readily apparent on the curves. Source : http://asia.vtec.net/beystock/honda/civicr/

Honda tune the R by hand

This is one of the factors why R are so limited, Honda using their experience and knowledge gained in the racing field and making use of it in their production lines for street cars. The Civic’s VTEC B16B type engine retained its stock displacement, but Honda increased its horsepower from 170 (B16A) to 185 (B16B). It’s only *15* horses more, but those 15 horses were really tweaked out using Honda’s formula 1 knowledge — from an engine that was already getting 100 horsepower per liter!

Currently, production line engines and engine parts are made by computer-guided NCR machines, and are of very high quality. However, Mr. Fumiyasu Suga (Type R’s assistant chief engineer) believes that in order to make a true race engine, some parts must be built/assembled by hand. In specific, the assembling of the engine, balancing parts, and porting and polishing need to be done by hand. Amazingly, all Type R engines are built this way. Source : http://www.superhonda.com

Piston

One of the keys to tuning a NA engine is the piston. In order to increase the compression ratio, aluminum, pent-roof-type pistons were used. In order to keep a good precision of mass, the aluminum pistons were forged. The piston ring was given more space to move around in, and to prevent piston “head” shake caused by the extra space, a molybdenum coating (also used in the NSX) was applied to lessen friction. Source : http://www.superhonda.com

The piston skirt was made lighter in order to lessen the inertial mass. Since lightening the piston causes the piston “neck” to rock back and forth, a molybdenum coating was applied to lessen friction.

In order to increase compression ratio, the side molds of the pistons were increased, from 10.4 to 10.8, The picture below shows you the differences between JDM Civic Type R B16B and JDM B16A Sir2 (EK4) P30.

Injectors installed on the underside of the pistons allow for improved cooling, and prevent the pistons from getting “burned-in”.

Block

For endurance, B16B used B18C spec R’s cylinder block, that mean it’s destroked from B18C and using same timing belt (Honda PN: 14400-P72-014, not compatible with B16A (14400-P2T-004)), also the engine bridge girdle and cylinder head bolts (90006-P72-003, 11×164) vs from B16A (90006-PG6-003, 11×155).

Connecting Rods

The con rods are specially made for the Type R. The precision weight of these con rods are 2 levels above that of on-line production models. The weight differential between all four rods is so small that it is negligible, and all contacting surface areas are finished off with a race-car, mirror finish, and is connected to a fully balanced crankshaft. Furthermore, the assembly of the con rods and the crankshaft play an important role in attaining the high rpm’s. In order to ensure perfect assembly, the engine is taken off-line and these parts are assembled by hand. A custom con rod micrometer gauge is used, and the stretching of the con rod bolt is taken into account for as the connections are tightened. This is something no machine can do, and this ensures that there aren’t any unwanted vibrations at high rpm. Source : http://www.superhonda.com

Custom-made connecting rods for the Type R. It is made to withstand the higher rpm’s, and is still lighter than the stock parts. These Type R parts are made with such precision that the weight difference between all four rods is so small that it is negligible.

B16B(77.4mm crankshaft and 142.42mm connecting rod) vs B18C (87.2mm crankshaft and 137.9mm connecting rod)

Hand Job Porting

The video below show the porting job for B18C 96spec R, the procedure is similar for B16B, by Honda Motor Co.,Ltd. Suzuka Plant mechanic,

Naturally, porting and polishing excessively won’t yield good results — it will only upset the balance between displacement and peak rpm’s. Some basic physics explained… In any cylindrical enclosure/piping, the closer air is to the metal wall, it will flow slower, and the closer it is to the center of the cylinder, it will flow faster. As rpm’s increase, slight variations in the enclosure will cause for serious air flow disturbances. Logically speaking, a straight, cylindrical port would prevent any problems of air-flow disturbance, but with street cars and their limited engine bay space, the port has to be bent.

The stock port is built to within such precision that it can already withstand rpm’s of up to 7,000 rpm without creating any unwanted air-flow disturbances, but once it reaches 8,200 rpm, the engine struggles to keep the air flowing smoothly. To augment this problem, two of the best mechanics at Honda were selected and assigned to manually port and polish the engine components. Though this limits production to 25 engines a day, this allows for the engine to reach 8,500 rpm, and respectively, 185 horsepower.

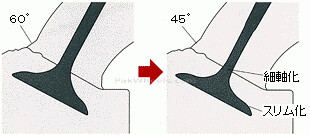

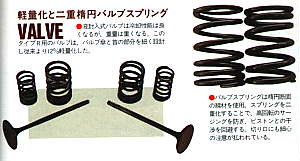

Valves and the Valve Springs

Next, the valves and the valve springs needed to be upgraded in order to be able to withstand the high rpm’s and the increased fuel injection. In order to increase air flow efficiency, the angle of the valve seat opening was tightened from 60 to 45 degrees. Also, bigger and lighter valves help to deliver more fuel. Instead of making the valve bigger, Honda engineers made the cone bigger and reduced the stem radius even further. In specific, the underside of the valve cone was shaved to its limit, and the valve shaft width was decreased from 5.5mm to 4.6mm — making the valve 12% lighter than stock. Amazingly, the valves are made so precisely that their static balance differential is basically 0.0. We jokingly asked Mr. Suga what he would do if Honda’s parts manufacturers sent over valves that had weight differences. His reply was quick and simple. “We would toss them out.” Hm… very strict. Past 8,000 rpm, other valve-related problems occur. Such problems include surging, jumping, bouncing, etc… In order to prevent such problems, the valve springs are made by dual-bound springs. Furthermore, Honda used non-cylindrical, “flat” springs in order to keep the spring height near-stock, and still increase rebounding power. Source : http://www.superhonda.com

B16B B18C Type R Intake Valves are same diameter as regular B-series valves but have distinct advantages in being 12% lighter in mass, with noticeably thinner valve stem from 5.5mm to 4.6mm, hence larger cone area and an improved contour for better air flow. Type R lightened intake valves are made so precise that their static balance differential is basically 0.0. Type R intake dual valve springs are specially made to work with Type R lightened intake valves for higher lift and rpm specifications. They are non-cylindrical, flat springs with increased rebounding power while their spring height are still near-stock. This will help to prevent valve-related problems past 8000 rpm such as surging, jumping, bouncing etc.

In order to prevent engine knocking at high rpm’s, NGK’s high-spark #7 platinums are used. Honda is so meticulous with its Type R production that it actually coats the spark plug tip with silicone so the spark plug doesn’t collect any unwanted deposits during the stop-and-go of transportation. (Wow… does that help any?)

Cams

The camshaft profiles (wild cam) change from B16A2 and B16B are :

Cam Profile

|

JDM B16A 170ps

|

B16B 98R

|

Max Lift (IN/EX)

|

10.7/9.4

|

11.5/10.5

|

Open Timing (IN/EX)

|

BTDC 15/BBDC 40

|

BTDC 18/BBDC 45

|

Close Timing (IN/EX)

|

ABDC 40/ATDC 7

|

ABDC 45/ATDC 10

|

BTDC = Before Top-Dead-Center, BBDC = Before Bottom-Dead-Center

ABDC = After Bottom-Dead-Center, ATDC = After Top-Dead-Center

The camshaft lift amount was changed for both intake and exhaust valves. The intake lift was increased from 10.7mm to 11.5mm, and the exhaust lift was increased from 9.4mm to 10.5mm. To compensate, the intake opening timing was increased from 15 to 18 degrees before piston apex, and closing timing was increased from 40 to 45 degrees after the piston reaching base. Likewise, the exhaust opening timing was increased from 40 to 45 degrees before the piston reaching base, and the closing timing was increased from 7 to 10 degrees after piston apex. By doing so, the valves remain open longer — allowing for more air to enter the combustion chamber.

Intake

To make sure the engine has a enough breath at the high RPM, the intake manifold was being modified (High-RPM type), the body is bigger and the plenums are short and fat compare to the B16A intake manifold.

The throttle bore diameter for B16B is identical to B16A at 60mm. This means that enlarged throttle bodies for B16A might not be an optimal mod or that a compromise in power delivery might result, eg loss of low-end power in return for gain in high-end power.

Crankshaft

Unlike the base crankshaft, additional balancing weights were added on number 1 and 4, and allows for smooth, high-rpm revving — making it a 8-weight, fully-balanced crankshaft.

The attachment point of the connecting rods to the crankshaft uses a new, adjustable connector that allows the mechanics to manually adjust the connection using a micrometer so they can compensate for the stretching of the connecting rod bolt.

Exhaust system

In order to make exhaust air flow smoother, there are no sharp angles in the header. Furthermore, in order to lighten/strengthen the parts, stainless steel was used.

Impossible to do in mass-production, all exhaust piping is welded together with no sharp edges throughout. Also, the piping was upgraded to 57.2mm throughout to increase air flow.

Impossible to do in mass-production, all exhaust piping is welded together with no sharp edges throughout. Also, the piping was upgraded to 57.2mm throughout to increase air flow.

The muffler is a multi-chamber design, and does a wonderful job of dissipating sound. However, the funnel-shaped piping in-between the chambers makes it a very free-flowing exhaust.

“In overview, over 60 engine-related parts were changed or entirely re-designed for the Type R. We asked Mr. Suga for any other advice on tuning the Type R any further. He replied, “I would prefer that people don’t try to further tune the Type R. No, actually, they shouldn’t try. Each upgraded part works in perfect harmony, and fiddling with the factory setting will only lead to a decrease in performance.” It’s probably safe to say that the Type R is a rare, “fully tuned” and “stock” automobile. ” Source : http://www.superhonda.com

I hope you will get some inspiration too!

No comments:

Post a Comment